High temperature bearings are essential components in various applications, especially those that involve extreme heat. With their ability to function and remain reliable despite such temperatures, these bearings have become an integral part of many industries.

But what is a high temperature bearing and how does it work? Here are three key things to know about this important type of bearing and their applications. First, high temperature bearings can be made from several different types of materials depending on the requirements of the application they’re being used for.

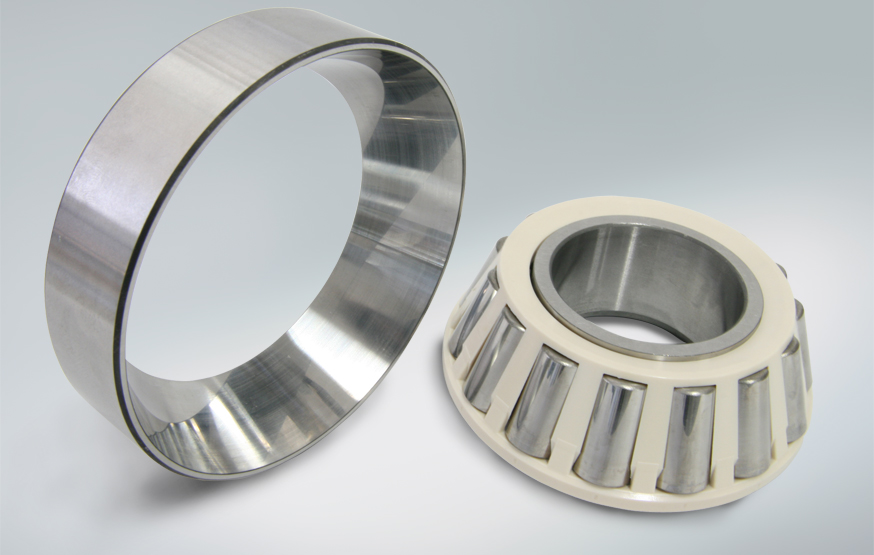

From metals like stainless steel or titanium to ceramic composites or other specialty materials, there are numerous options available when it comes to choosing the right material for your specific application.

Key Characteristics of High Temperature Bearings

High temperatures can have a detrimental effect on the performance of bearings, making it important to understand the key characteristics and features that make them suitable for use in high temperature environments. It is essential that high temperature bearings are constructed from materials with excellent thermal stability, as well as having good dimensional stability under extreme temperatures.

Additionally, they should feature an effective lubrication system to protect against wear due to friction and heat build-up during operation. High temperature bearings should also be designed with wide contact angles and deep grooves which help maintain load capacity even at elevated temperatures.

Finally, these types of bearing must have a robust sealing system in place to protect against dust particles and other contaminants which may cause premature failure or damage when exposed to high temperatures.

Benefits of Utilizing High Temperature Bearings

High temperature bearings have numerous benefits. They are designed to withstand extreme temperatures and can therefore be utilized in a wide range of applications, from automotive manufacturing parts to aerospace components.

One major benefit is the low maintenance costs associated with high temperature bearings since they require less lubrication than traditional ones. Additionally, these bearings last longer due to their superior heat dissipation capabilities, meaning fewer replacements over time.

Furthermore, high temperature bearings offer improved safety compared to other types of bearing as they do not generate sparks or cause fire hazards when used in industrial settings. Finally, these bearings are more cost-effective compared to traditional models and require minimal installation time due to their compact design.

All of these factors make high temperature bearings an ideal choice for many industries requiring reliable performance under extreme conditions.

Common Applications for High Temperature Bearings

High temperature bearings are a type of specialized bearing used in extreme heat applications. They are designed to withstand temperatures up to 300°C and can be found in many industries, from aerospace and automotive to construction and power generation.

Common applications for high temperature bearings include: Aerospace: High temperature bearings play an important role in helping aircraft engines operate safely and efficiently at higher altitudes where temperatures can exceed the maximum limit of standard bearings. These types of bearings also enable further safety by providing additional protection against engine failure due to overheating or other issues related to high-temperatures during flight.

Automotive: In the automotive industry, high temperature bearing solutions help create more efficient vehicle designs as they allow engines and other vital components to function properly at higher temperatures without compromising performance or reliability.

Conclusion

and applications two times High temperature bearings are an essential component in many modern industrial applications. They offer reliable performance under high-temperature conditions, providing the necessary support for machines that operate in extreme environments.

By understanding key features of these components, such as their ability to withstand elevated temperatures and their wide range of uses, engineers can make better decisions when selecting a bearing for a specific application. With this knowledge, they can select the right high temperature bearing to ensure optimal results and long-term reliability.